Electric Heaters and Elements

Band Heaters are used to heat (mostly) cylindrical surfaces and are available in several construction styles to perform under different operating environments.

Typically inserted into drilled holes to heat platens and molds or used as liquid immersion heaters.

Used in plastics processing, food warming, semiconductor manufacturing and other industries, Cast-In Thermal Components are available in aluminum and bronze alloys and are highly customizable.

The heat source combined with a high temperature insulation allow for high operating temperatures up to 2012°F/1100°C. Higher temperature ratings up to 2192°F/1200°C are available in limited designs.

The flexibility of mineral insulated cable allows the Mightyband® heater to be coiled, formed, wrapped around pipes or used straight. It can also be cast into metal or welded onto machine component parts.

Speed the flow of solid and semi-solid materials inside your industrial drums with a drum heater from Tempco. We carry five drum heaters and offer two methods of heating the materials: immersion within the drum or heating from the outside of the drum.

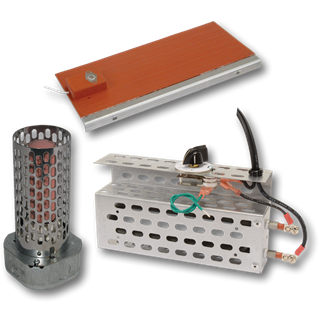

Designed to protect a wide variety of applications from low temperatures, condensation and corrosion.

Capable of operating with excellent performance under many adverse conditions, the low thermal mass of flexible heaters allows their use in applications where the space for placing a heater is limited and weight is a concern.

Heat trace cables are used to counteract the effects of heat loss from process piping systems.

Electrically heated hose assemblies are designed for optimum transfer of non-explosive liquids or gases.

Infrared radiant heat energy can be delivered to concentrated areas at a very fast rate with individual heaters or heater arrays.

Explore Tempco’s full line of industrial process heaters, including electric duct heaters, circulation heaters, immersion heaters, and tubular elements. Engineered for reliable heating of air, liquids, and gases in demanding applications.

Our turnkey air-cooled shroud systems provide efficient heating and cooling of the barrels in plastic extruders.

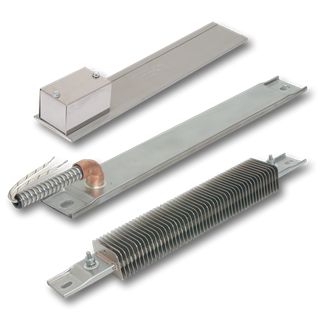

Used in the surface heating of tanks, as the heat source in industrial ovens and for heating air or other inert gases.

We offer a wide variety of tank and chemical bath tank heaters to fit your application.

Available in several diameters, lengths and sheath materials, these heaters can be formed into virtually any shape and can be brazed or welded to any metal surface. Choose specific application finned heaters or heaters for runnerless molds.