A Critical Challenge for the Oil Industry

An international manufacturer and supplier of connectors for the oil industry came to Tempco with a complex challenge. They needed a reliable way to heat and cool a 316 stainless steel vessel containing a mix of water and hydrocarbons, pressurized with an inert gas. The vessel would be used to age their connectors as part of a qualification test, and the company needed a solution to cool it down efficiently and safely.

However, there was a problem. The vessel manufacturer had imposed strict limitations on the heating and cooling rates due to the unique properties of 316 stainless steel. This material, while corrosion-resistant, does not transfer heat effectively and can develop dangerous thermal stresses when the heating or cooling rate is too high. The challenge was clear: how could Tempco design a system that met the vessel's cooling requirements without exceeding these limits?

The Cooling Requirements: A Tight Deadline and Strict Limits

The customer's goal was to cool the vessel from 650°F down to 70°F, a drastic temperature change. They knew they could achieve this using liquid cooling, but they had concerns about the complexity of a liquid cooling loop. They wanted to avoid dealing with the fluid, heat exchanger, and other components that typically come with liquid cooling systems.

Instead, they asked Tempco if it was possible to use a more straightforward system that would meet the strict cooling rate requirement. Specifically, the vessel manufacturer had limited the cooling rate to just 120°F per hour at the outer diameter of the vessel.

The customer initially considered using finned cast aluminum heaters paired with an air-cooled shroud system, but they were uncertain if this solution could meet the target cooling rate of 300°F/hr. Tempco was tasked with finding a solution that would work within these constraints.

Tempco’s Approach: Collaboration and Expertise

Tempco's team immediately began working closely with the customer to understand the full scope of the project. They reviewed cooling calculations, exchanged detailed technical information, and evaluated the most effective ways to achieve the required cooling rate without risking thermal stress to the 316 stainless steel vessel.

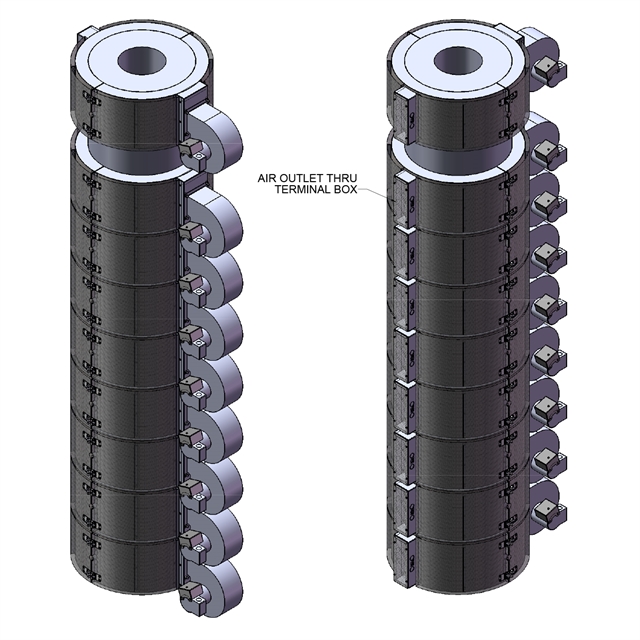

Tempco's engineers used their expertise to determine that an air-cooled solution could meet the customer’s needs. The team proposed using finned cast aluminum heaters combined with a low CFM centrifugal blower and a Cool-to-the-Touch air-cooled shroud system. This system would allow for precise control of the cooling rate, ensuring it stayed within the vessel manufacturer’s strict limits.

The Solution: Air-Cooled System with Reliable Performance

Tempco’s custom solution was a breakthrough for the customer. The air-cooled shroud system with finned cast aluminum heaters and the centrifugal blower met the critical cooling rate while avoiding the complications of a liquid cooling system. The solution provided several key benefits:

- Precise Cooling Control:The system maintained the cooling rate within the strict limit of 120°F per hour, preventing thermal stress on the 316 stainless steel vessel.

- No Liquid Cooling Hassles: The customer was able to avoid the complexity of a liquid cooling loop, which included managing fluids, heat exchangers, and potential maintenance issues.

- Faster Turnaround: Tempco's quick design and manufacturing process allowed them to deliver the entire system in less than five weeks.

Successful Delivery: Meeting the Customer's Needs

From design to manufacturing, the entire system was delivered to the customer in less than five weeks. The custom cooling system was delivered on time, meeting all technical requirements. Tempco’s collaboration with the customer ensured that the solution was precisely what they needed for their qualification testing. The air-cooled system provided reliable performance, helping the customer age their connectors safely and efficiently.

For companies in the oil industry, Tempco offers fast, reliable, and customized heating and cooling systems that help solve even the most difficult challenges—delivered on time and with precision.