Answers to 7 Common Cartridge Heater Questions

From Tempco's Heater Experts

October 11, 2024

Please wait while we gather your results.

Related Articles

Tempco designed and manufactured hi-density cartridge heaters for an original equipment manufacturer of small and large format heat press machinery.

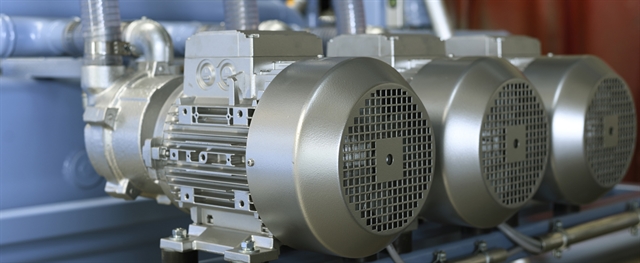

Tempco provided a custom Pipe Heater for our customer who manufactures vacuum pumps for many industrial applications.

We designed and manufactured high density cartridge heaters for training equipment that is used to highlight the thermal loop of an immersion tank heating system.

Tempco designs and manufactures the best solutions for specific applications in the medical and healthcare industry. Learn about our engineering expertise that can support you - from medical-grade tubing production to health and wellness applications.