Recommendations for Improving the Life of Hi-Density Cartridge Heaters

Please wait while we gather your results.

Related Articles

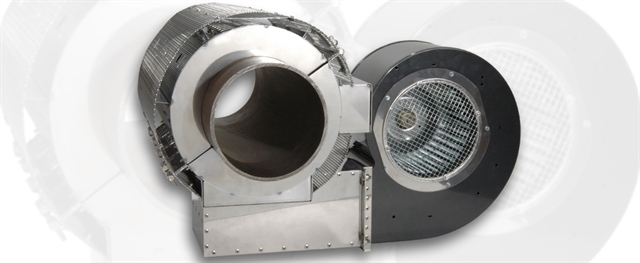

Improve efficiency in your extrusion process with Tempco's Air-Cooled Shroud Systems constructed with either sheet metal or cast aluminum.

Power variations are an important feature of Tempco's channel strip heaters. Learn about the 5 different power variations and how they allow for design flexibility to fit your application needs.

Learn all about Tempco's Silicone Rubber Heaters including: typical applications, construction characteristics, wattage recommendations, heater performance and custom design samples.

Learn about Tempco's Tubular Heaters including: Typical Applications, Construction Characteristics, Watt Density information and more.