All about Tempco's Air-Cooled Shroud Systems

Custom Shroud Systems

Helpful Links

Please wait while we gather your results.

Related Articles

Tempco’s guide to air-cooled shroud systems shows how to improve efficiency, reduce costs, enhance temperature control, & boost safety with easy setup & energy savings.

A manufacturer and supplier of connectors for the oil industry required the heating and cooling of a vessel used for in-house testing. Tempco designed and manufactured a Cool-to-the-Touch shroud system for the application.

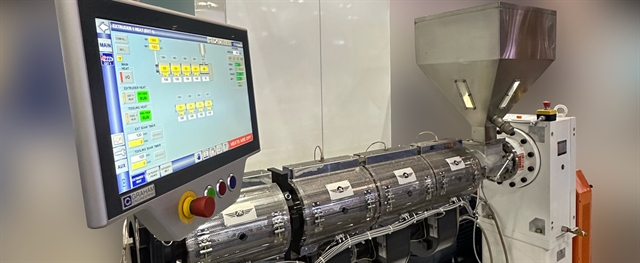

A plastics extruder service and rebuilding company faced a unique extruder design that required a custom, Cool to-the Touch shroud system.