Custom Shroud System for Plastics Extruder

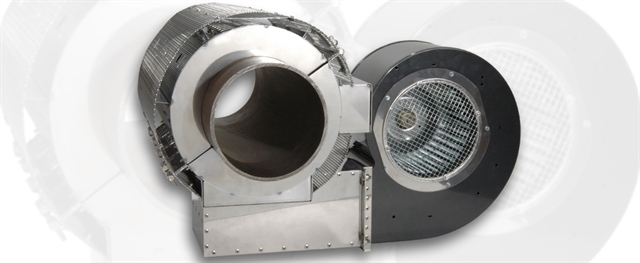

Custom Cool TO-THE Touch Shroud System for Extruder

April 17, 2019

Please wait while we gather your results.

Related Articles

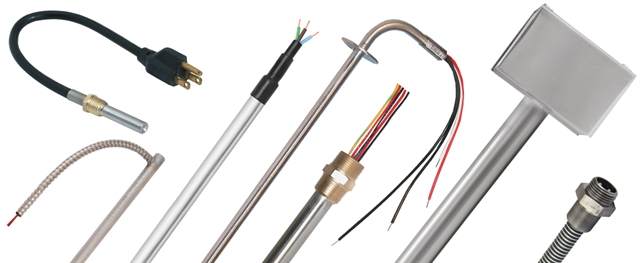

Explore the construction, uses and benefits of Tempco's cartridge heaters and discover how they can work for your industrial application.

Improve efficiency in your extrusion process with Tempco's Air-Cooled Shroud Systems constructed with either sheet metal or cast aluminum.

A leading engineering firm who was developing an oven system for research and development looked to Tempco to design and manufacture duct heaters for the tentering process.

A manufacturer in the Sheet Film Industry needed a large, custom control panel that adhered to UL 508A standards.