All About Tempco's Tubular Heating Elements

All About Tempco's Tubular heating Elements

Common Applications

Custom Tubular Heater Designs

Helpful Links

Please wait while we gather your results.

Related Articles

A manufacturer in the transportation industry specifies Tempco Finned Tubular Heaters for their heating units that maintain a comfortable temperature in locomotive cabs during the winter.

Learn about the product characteristics that are important when specifying Tempco's tubular heating elements for your commercial, scientific or industrial application.

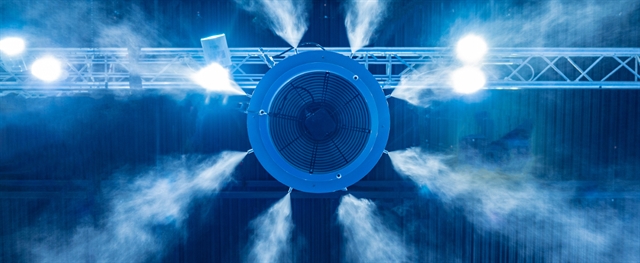

Tempco provided engineering and manufacturing expertise with ideal lead times to a new customer who had an immediate need for tubular heaters that are used in the manufacturing of industrial humidifiers.

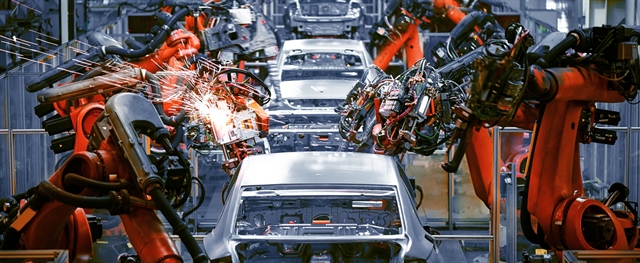

Tempco custom-designed an L-shaped Tubular Heater to work within a portable machine parts washing system for the automotive industry.