Long-Life Cartridge Heaters: Cost-Effective Heat Press Solution

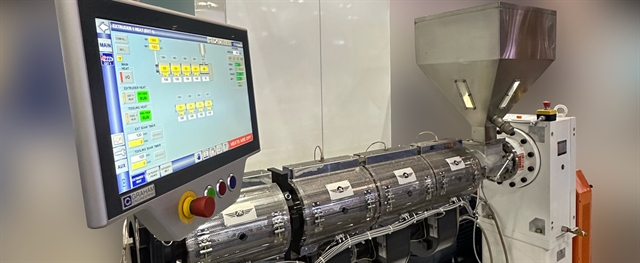

Reliable OEM Parts from Tempco

Updated: October 24, 2024

Please wait while we gather your results.

Related Articles

Get even heat for oils and non-corrosive fluids. Aluminum-finned Flanged Immersion Heaters provide safe, even heat.

Use Tempco's guide to choose the right control product for your industrial application and improve your efficiency, safety and product quality.

Tempco’s guide to air-cooled shroud systems shows how to improve efficiency, reduce costs, enhance temperature control, & boost safety with easy setup & energy savings.

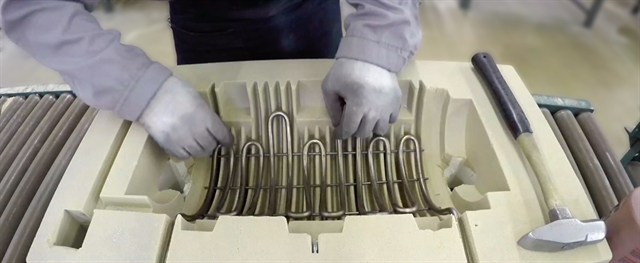

Learn how investing in high-quality cast-in heater molds & precision heater patterns improves production efficiency, reduces defects, & boosts customer satisfaction.