Sand Molds and Their Crucial Role in Casting Quality

The Role of Skilled Workers in Pattern Making

The quality of the pattern depends heavily on the skills and experience of the workers who craft the patterns. At Tempco, our workers are experts in their field and use state-of-the-art technology to create patterns.

The quality of the pattern depends heavily on the skills and experience of the workers who craft the patterns. At Tempco, our workers are experts in their field and use state-of-the-art technology to create patterns.

They have been trained to interpret design drawings with a high degree of precision, ensuring that each pattern is made to the exact specifications required. The high retention rate of our employees, along with a strong culture of cross-training, means that our team is both experienced and flexible, able to handle a wide variety of complex pattern-making tasks.

Quality Patterns Make a Difference

High-quality patterns contribute directly to better product performance and fewer defects like air pockets or material voids.

High-quality patterns:

- Reduce rework resulting in shorter lead times.

- Minimize scrap that ensures long-term value and savings passed on to our customers.

- Get you up and running quicker with smooth installation and less downtime.

- Improve operational efficiency with a reliable and durable product.

These are four significant cost drivers for any manufacturing operation and by addressing them during initial design you can reduce costs later.

The Benefits of Sand Molds

Sand molds offer several advantages when it comes to casting heater elements. They allow for more creative freedom in designing complex geometric shapes. They also offer a cost-effective solution for low to medium-volume production. And can be a good way to prototype a casting for testing and development before transitioning to high-volume production.

Sand molds are versatile and can accommodate a wide range of alloys, including aluminum, brass, and bronze. Learn more about alloy properties to choose the best alloy for your project. Additionally, sand casting is ideal for producing unique or custom parts quickly.

The Manufacturing Process: From Design to Final Product

The journey to a high-quality cast-in heater starts long before someone pours molten metal into the mold. Here's a look at the key steps involved in creating a precision heater mold:

- Design – The process begins with making detailed designs using programs like SolidWorks and AutoCAD to meet the customers’ requirements.

- Pattern Creation – After we finish the design, we send it to our in-house pattern shop where skilled workers make the pattern to exact specifications using state-of-the-art technology.

- Mold Making – The pattern is then used to create the cavity in the sand mold, which will form the casting. Sand molds are ideal for creating complex shapes and low to medium-volume castings quickly and efficiently.

- Casting – Molten metal is poured into the mold, where it cools and solidifies. The casting is then removed and prepared for machining, where it is worked to meet the customer’s exact specifications.

- Machining – The casting is machined to the required dimensions, tolerances, and surface finish. In some cases, the casting may require minimal to no machining, depending on the complexity of the part.

- Finishing – The threaded posts or lead wire connections are added to the heating elements and all surfaces are cleaned. The heater is visually inspected and electrically tested before it is stamped for identification and tracking.

- Final Quality Assurance – We conduct visual, dimensional and electrical tests to ensure that every casting meets our high standards for accuracy and finish using calibrated equipment.

Unique Techniques at Tempco

At Tempco, we pride ourselves on our ability to create custom heaters that meet the most exacting requirements. We use creative methods to position and hold the formed elements in the correct location within the mold, ensuring that the castings meet the desired specifications. Our expertise in sand molding and tilt-pour gravity feed techniques sets us apart from the competition.

Our ability to accommodate a range of complex designs—from large, intricate shapes to smaller, precision parts—allows us to meet the unique needs of our clients, delivering high-quality castings.

November 14, 2024

Please wait while we gather your results.

Related Articles

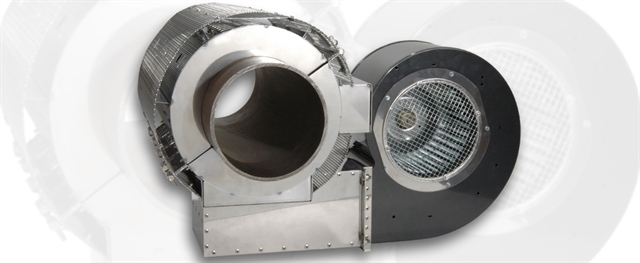

Tempco’s guide to air-cooled shroud systems shows how to improve efficiency, reduce costs, enhance temperature control, & boost safety with easy setup & energy savings.

Tempco utilized flow simulation software to assist in the discovery, design and manufacture of the ideal circulation heaters for a customer's test setup.

Improve efficiency in your extrusion process with Tempco's Air-Cooled Shroud Systems constructed with either sheet metal or cast aluminum.

Tempco designs and manufactures the best solutions for specific applications in the medical and healthcare industry. Learn about our engineering expertise that can support you - from medical-grade tubing production to health and wellness applications.