Optimization Tests for Heating Autoclaves

Optimization Tests for Heating Autoclaves

July 8, 2021

Please wait while we gather your results.

Related Articles

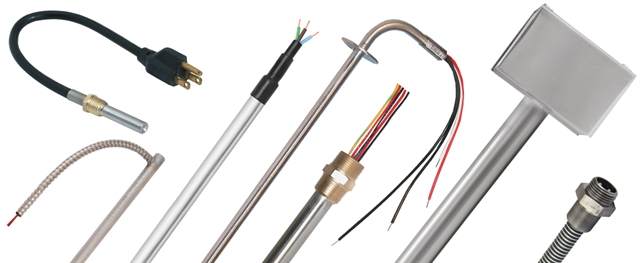

Explore the construction, uses and benefits of Tempco's cartridge heaters and discover how they can work for your industrial application.

One OEM and medical device manufacturer specifies Tempco products for precise heating and accurate temperature sensing in their application.

Tempco worked with a refrigerator door manufacturer to design a tubular heater that was ideal for their innovative product line.

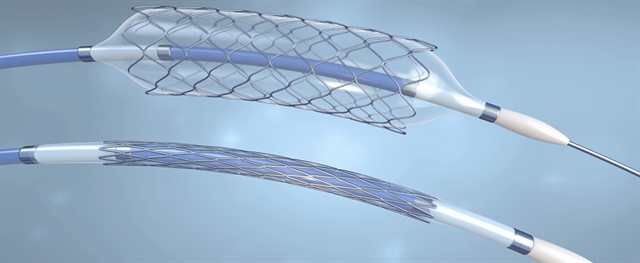

Tempco worked closely with our customer in the medical services industry to develop a miniature inline circulation heater that met all necessary project specifications for use in a portable hemodialysis system.