Wind tunnels play a crucial role in testing how air flows around objects like vehicles, aircraft, and other large structures. These tests help companies in industries such as aerospace, automotive, and engineering develop better, safer designs for transportation, energy, environmental, and architectural applications.

To obtain accurate results, air in wind tunnels need to meet specific temperature and flow rate conditions. This is where custom heating solutions come in. A wind tunnel and testing facility design company needed a custom duct heater. This heater would fulfill the heating requirements of a large wind tunnel for large trucks and buses.

This custom heating system needed to work reliably, meet safety standards and fit well into their HVAC system.

Rising to the Challenge: A Custom Large Wind Tunnel Duct Heater

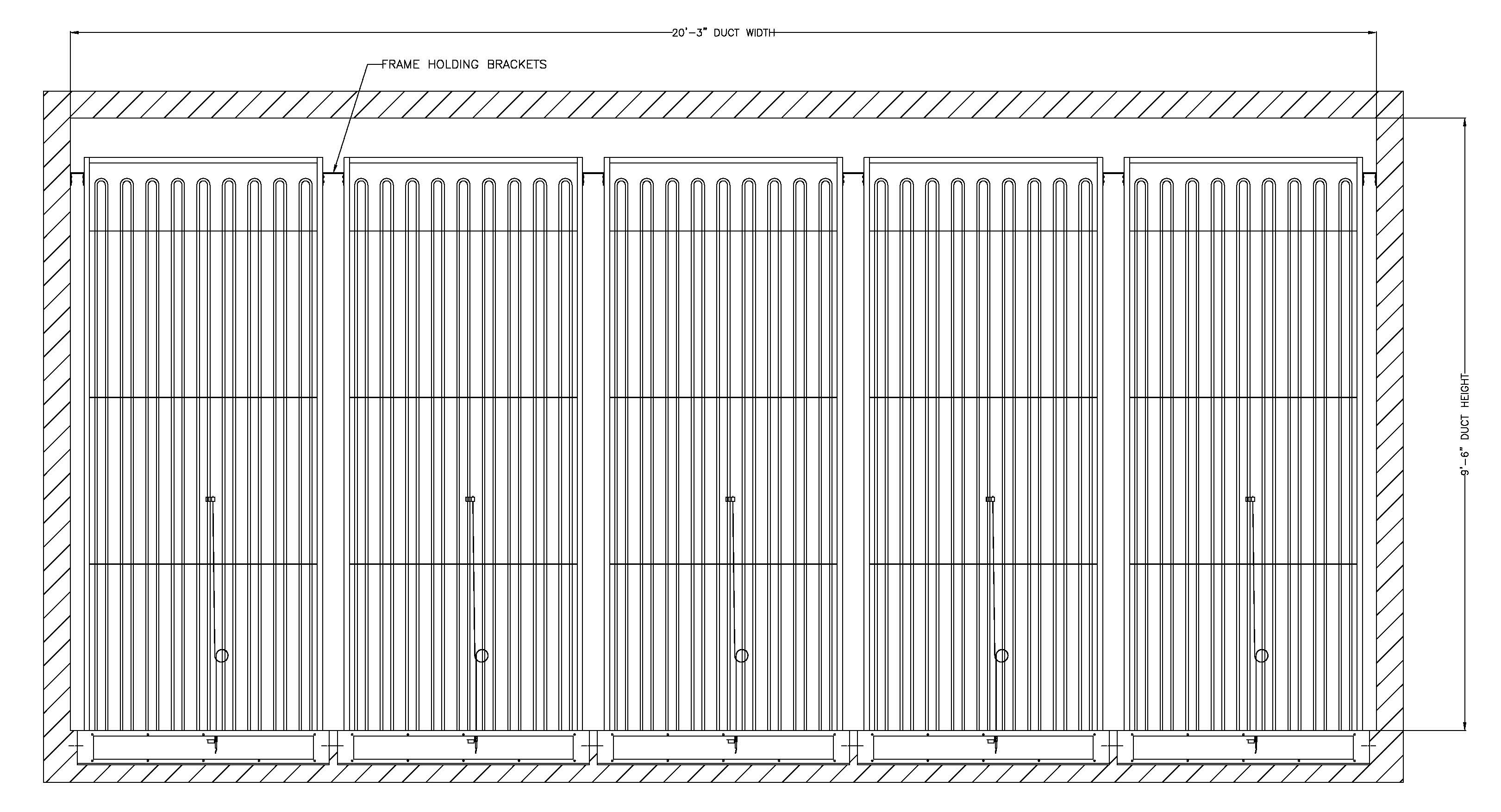

The air duct where the duct heater was to be installed was 20-1/4 feet wide and 9-1/2 feet high. The system had to heat the air uniformly and maintain precise temperature control for accurate testing. Several factors made this a complex task:

- Even Heat Distribution: The heater must provide evenly heated air through the ducts. This helps eliminate cold spots and ensures that the processed air meets the wind tunnel’s variable test conditions.

- Variable Airflow: The wind tunnel's airflow varies from 300 to 1,075 feet per minute. This meant the heater needed enough power to heat fast moving air at different flow speeds.

- Wide Temperature Range: The duct heater needed to keep temperatures between 30°F and 150°F. This simulates different conditions for vehicle testing.

The design needed to be reliable, adaptable, and powerful enough to meet these demanding requirements.

The Design Process

To meet the customer’s needs, a highly custom duct heater was developed through multiple design iterations. The foci were on heat output, safety, and easy installation. Here's how the design evolved:

- Multiple Heater Assemblies: The system has five heating assemblies. Each assembly has 18 heating elements. This setup ensured that the heat distributed evenly across the entire cross-section of the air duct, even with varying airflow speeds.

- Thermal Management for Safety: Given the high total wattage—200 kW—and the varying airflow speeds, it was crucial to manage the heat output effectively. The team gave special attention to thermal management to prevent overheating, ensuring safe and reliable operation.

- Easy Installation with Custom Frame: The custom heating system was designed to be easily installed into the wind tunnel. A steel frame around the heating elements to allow for quick mounting inside the duct. The frame was made to be strong and simple so it can be securely placed and aligned during installation. It, along with the element separators, provides stability to the heating elements and maintains their upright positions.

- Custom Electrical Housing: A custom terminal housing allowed for easy electrical connections and has several access points for wiring. This housing accommodated for the connection of multiple heater assemblies in parallel. It also ensured that all electrical parts were mounted safely and remained easy to reach.

Thermal Control and Safety Features

Given the high power required for this heating system, maintaining safe operation was a top priority. The system needed to provide 200 kW of power while ensuring that the heating elements didn’t overheat.

Hi-Limit Thermocouple: A hi-limit thermocouple is used to monitor the temperature of the heating elements. This sensor measures the temperature of the element’s outer sheath. If the high temperature exceeds safe limits, the system automatically shuts down to avoid damage.

Manufacturing the Custom Duct Heater

The manufacturing team focused on precision, safety, and quality control to ensure the custom duct heater met the performance requirements.

- Frame Alignment and Element Spacing: The frame was carefully welded to maintain precise alignment with the flanges. The engineers spaced the heating elements evenly for uniform heat distribution. Any sagging or misalignment can cause uneven heating, so special care was taken during manufacturing to ensure the elements remained straight and upright.

- Final Inspection and Quality Control: Each assembly underwent thorough quality checks. These checks included dimensional inspection, electrical testing, visual inspection, and verifying that the materials met the specifications. By closely monitoring these details, the team ensured that the custom duct heater would perform exactly as designed when installed in the wind tunnel.

Collaboration and Communication for Success

The success of this custom heating project came from productive communication between the manufacturer and the customer. During the design and manufacturing process, the engineers worked closely with the customer. They wanted to understand the customer's needs and change the design as needed.

By gathering all the necessary information upfront, the engineers were able to create an effective and reliable solution. Clear communication helped make sure the final design met the customer’s needs. This reduced the chances of expensive design changes, reworking, and delays.