Infrared Heat Ideal for Thermoforming Process

Infrared Heat Ideal for Thermoforming Process

Precision Heating for High-Quality Production

How one electronics company found a custom heating solution for thermoforming with infrared heat.

When a large, well-known consumer electronics company approached Tempco, we listened. They needed a reliable high-heat solution for plastic parts within their manufacturing process. As these parts enter the manufacturing stage known as indexing, the plastic components are constantly being shifted into new positions with quick, precise movements. During this stage, heat needs to be applied to the parts.

The plastic part is placed on a large plate and is contained inside a 2-inch target area. It requires precise and strict temperature uniformity. In addition, it must be evenly distributed to ensure a high level of quality during the thermoforming process.

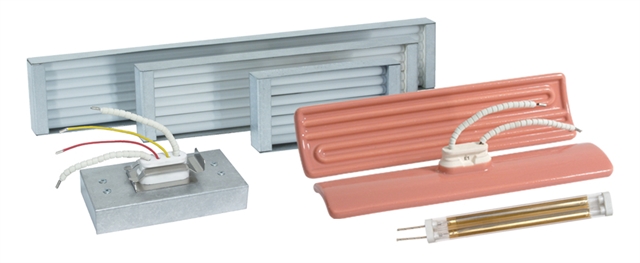

Introducing Tempco’s Type CRG Heater

Tempco manufactures a variety of ceramic e-mitters for the plastics industry. After carefully considering application details, we suggested that the customer use a Type CRG heater.

Tempco manufactures a variety of ceramic e-mitters for the plastics industry. After carefully considering application details, we suggested that the customer use a Type CRG heater.

KEY ADVANTAGES OF THE TYPE CRG HEATER

- Diverse Wattage Options: Tailor the heater to various wattages to suit the precise heating needs of the plastic parts.

- Compact Square Shape: Its efficient square design fit seamlessly into the customer's existing metal frame, providing effective heating without extensive modifications.

SPECIALIZED FEATURES FOR OPTIMAL PERFORMANCE

To improve the heater's performance, a team of engineers collaborated to create a solution that fits the customer's needs. Two additional features were utilized:

- Efficient Heat Management: A system of Type CRG heaters was designed for the application’s metal frame that minimized heat loss and reflected maximum heat on the plastic parts.

- Accurate Temperature Control: To meet strict temperature uniformity requirements, our team integrated a thermocouple into the body of the ceramic infrared heater. This feature allows for precise control over the heater, assisting the heater to maintain the exact temperature needed for consistent, high-quality results.

Transform Your Manufacturing Process with Tempco

Tempco is dedicated to delivering effective heating solutions that meet the needs of the plastics manufacturing industry. Our Type CRG heater, with its customizable wattage, compact design, and practical features, is designed to optimize your production process.

Ready to enhance your plastic manufacturing operations? Contact Tempco today to learn how our Type CRG heater can make a difference in your production line. Our team of experts is ready to provide tailored solutions and support for your heating needs.

August 21, 2020

Please wait while we gather your results.

Related Articles

Discover why Tempco's Ceramic E-mitters are ideal for use within the health and wellness industry.

Tempco designed and engineered an infrared radiant heater to meet the requirements of a secondary drying operation for an automotive OEM supplier.

Infrared technology proved to be the ideal solution for Tempco's customer in the aerospace industry whose application required rapid response and intense heat.

Infrared heat energy can be delivered to concentrated areas at a very fast rate with Tempco's Radiant Heaters or heater arrays.