Finned Channel Strip Heaters for Precise 3D Printer Application

August 23, 2022

Please wait while we gather your results.

Related Articles

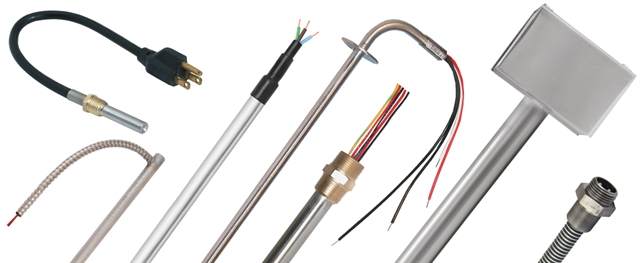

Explore the construction, uses and benefits of Tempco's cartridge heaters and discover how they can work for your industrial application.

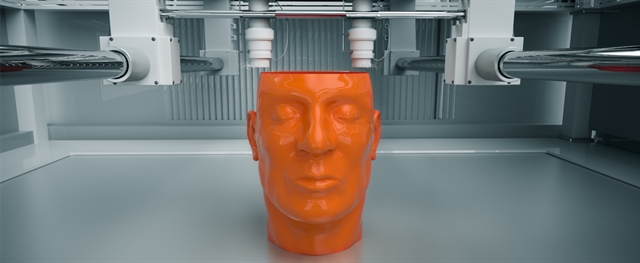

A leading U.S. Additive Manufacturing Company approached Tempco to have a heater with precise temperature control designed for their application.

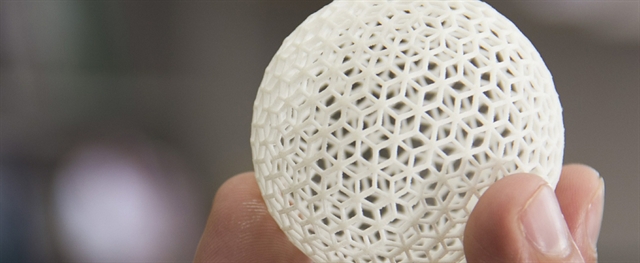

Three unique silicone rubber heater designs allow our customer in the 3D printing industry to precisely pre-heat nylon powder.

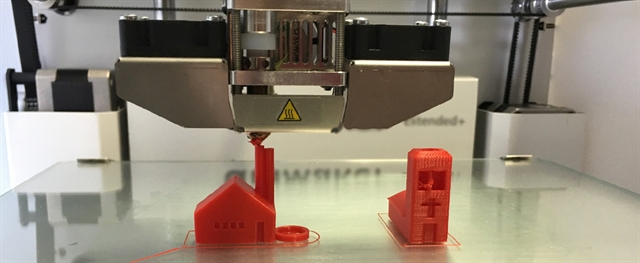

Tempco manufactured a Coil Heater to satisfy the requirements of a 3D Printer Manufacturer's application.