Silicone Rubber Heaters for Powder Cart Assembly

SILICONE RUBBER HEATERS PRE-HEAT NYLON POWDER CART

October 30, 2019

Please wait while we gather your results.

Related Articles

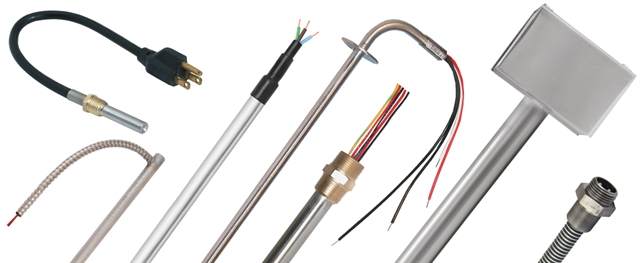

Explore the construction, uses and benefits of Tempco's cartridge heaters and discover how they can work for your industrial application.

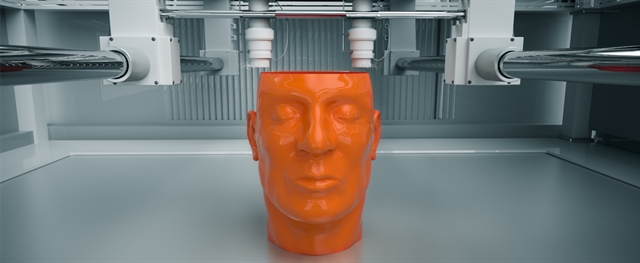

Tempco worked with our customer in the additive manufacturing industry to design and manufacture multiple heater designs until their application requirements were met.

A leading U.S. Additive Manufacturing Company approached Tempco to have a heater with precise temperature control designed for their application.

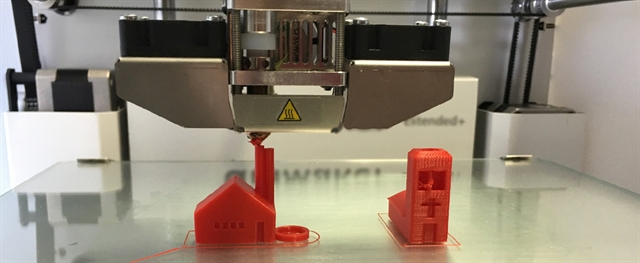

Tempco manufactured a Coil Heater to satisfy the requirements of a 3D Printer Manufacturer's application.