Enhancing FlUid Flow:

Flexible Heaters for Viscosity Control

Updated September 10, 2024

Please wait while we gather your results.

Related Articles

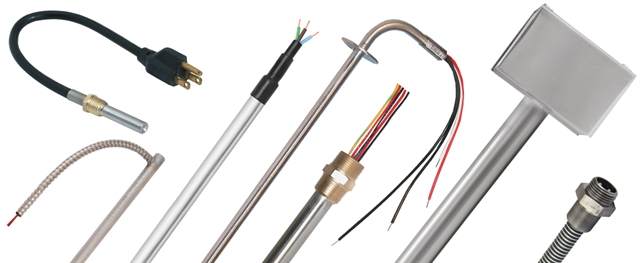

Get even heat for oils and non-corrosive fluids. Aluminum-finned Flanged Immersion Heaters provide safe, even heat.

Explore the construction, uses and benefits of Tempco's cartridge heaters and discover how they can work for your industrial application.

Tempco designed a large, high-powered immersion heater for a water processing application.

Tempco worked with our customer in the additive manufacturing industry to design and manufacture multiple heater designs until their application requirements were met.