Thermocouples are one of the most common and practical types of temperature sensors. They are reliable, durable, cost-effective and can operate at high temperatures. Each thermocouple consists of two different conductors or thermoelements that produce an electromotive force (EMF), a miniscule voltage, when heated. These thermoelements are made of different alloys which are better known as calibration types. Calibration types are standardized based on the type of alloys used to formulate each thermoelement and their pairing. Due to variations in these alloys and the differences in their physical, mechanical and chemical properties, care must be taken to select the appropriate type of calibration.

8 Main Thermocouple Calibration Types

According to the American National Standards Institute (ANSI) there are 8 main thermocouple calibration types, with the two most common types being J and K. They are listed in standard ASTM E230 as:

Type B – Platinum-30 % rhodium (+) versus platinum6-% rhodium (−)

Type E – Nickel-10 % chromium (+) versus copper-45% nickel (constantan) (−)

Type J – Iron (+) versus copper-45 % nickel (constantan) (−)

Type K – Nickel-10 % chromium (+) versus nickel-5 % (aluminum, silicon) (−)

Type N – Nickel-14 % chromium, 1.5 % silicon (+) versus nickel-4.5 % silicon-0.1 % magnesium (−)

Type R – Platinum-13 % rhodium (+) versus platinum (−)

Type S – Platinum-10 % rhodium (+) versus platinum (−)

Type T – Copper (+) versus copper-45 % nickel (constantan) (−)

Read more at the ANSI Blog: Thermocouples: Calibration Tables, Types, Specifications, and Standards

Deciding which calibration type to choose for your application can depend on a few factors such as:

- temperature range of application being measured

- the size of the wire used to create the sensor

- the age of the temperature sensor

Temperature Being Measured

The first factor to consider is the temperature range of what is being measured. There is an operating temperature range for each thermocouple calibration type. The maximum temperature will vary based on the size of wire used to produce the thermocouple. Additionally, each calibration type also has a different tolerance range.

See Temperature Sensors: Tolerances & Temperatures for Table 1 that shows calibration type and temperature range as well as standard and special tolerances, courtesy of ASTM.

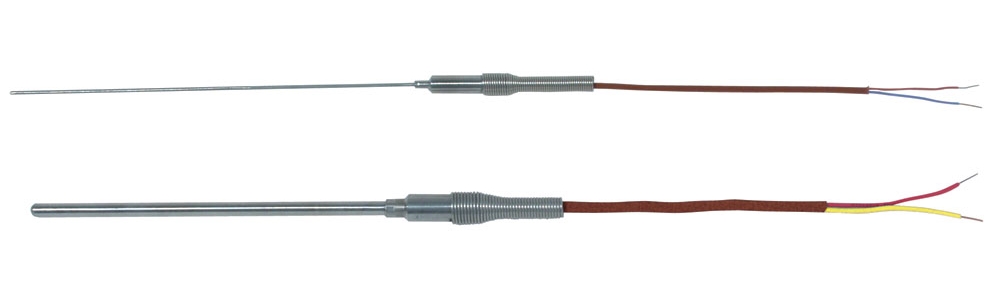

MTA1 MI Cable TC Assembly Thermocouple Assembly - MTA: Transition to Lead Wire

Size of the Wire

Another factor to consider is the size of wire used to create the thermocouple. Wire size can lower the upper temperature limit. Publications on temperature sensors will list that Type K thermocouples have an upper temperature limit of 1260°C because that is the upper limit for 8-gauge wire. However, when a thermocouple is constructed using 24-gauge wire, the recommended upper temperature limit is only 870°C. These limits only apply to tube & wire style thermocouples, which are thermocouples in conventional, closed-end protection tubes. The limits do not apply to sheathed thermocouples having compacted mineral oxide insulation.

See Temperature Sensors: Tolerances & Temperatures for Table 2 that shows calibration type and the corresponding upper temperature limits per wire gauge, courtesy of ASTM.

Thermocouple Aging

The last factor to consider is thermocouple aging. Thermocouples can degrade over time due to the environment in which they are used. Thermocouple alloys will oxidize and/or corrode over time. Type K thermocouples are sometimes favored over Type J due to their ability to withstand higher temperatures for longer periods of time. Type J has an iron leg, which is prone to degrade faster than other alloys. However, when cycling at very high temperatures, Type K thermocouples will see a change in the composition of the alloy. This will cause a drift in temperature readings due to a phenomenon called hysteresis. Thermocouple hysteresis is a change in sensitivity of a thermocouple, its temperature coefficient and EMF, as it cycles and moves through a sequential range of temperatures.

When choosing the proper thermocouple calibration type, it is very important to consider these factors. If you are unsure of which calibration type you should choose for your application, contact Tempco for guidance. Tempco offers a complete line of Temperature Sensors to meet your application needs.