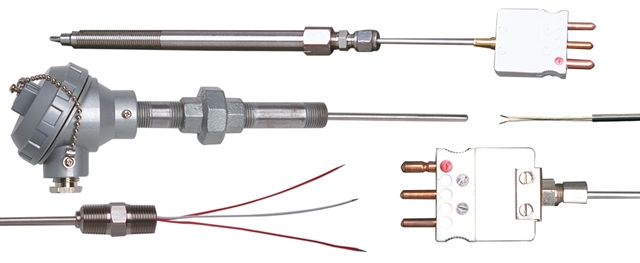

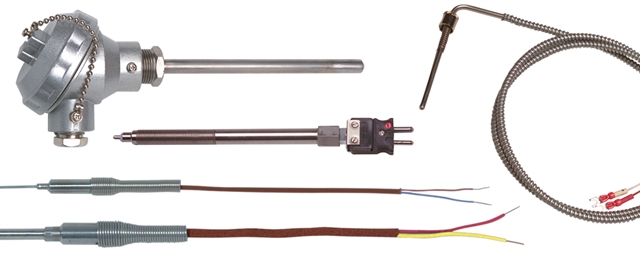

Thermocouple Mounting Styles

Comparing Thermocouple Mounting Styles: Bayonet, Melt Bolt, Clamp & More

Weighing The Options

Related Articles

Please wait while we gather your results.

Thermocouple Mounting Styles

From bayonet to clamp-on, learn how thermocouple mounting styles impact accuracy, install ease, and process performance—plus how to choose the right one.

True RTD Accuracy – What You Need to Know!

A Tempco engineer compiled the most important factors to consider when designing a Resistance Temperature Detector (RTD) and describes how those factors can affect accuracy in your application.

Thermocouple Calibration Type Selection Guide

A Tempco engineer lists several factors that affect thermocouple calibration and explains why they are important to keep in mind when making a thermocouple selection for your application.

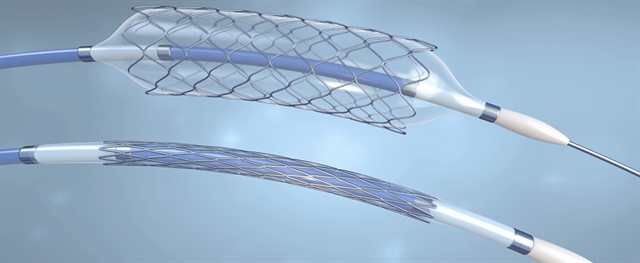

The Impact of Tempco’s Heaters and Temperature Sensors on Medical Devices

One OEM and medical device manufacturer specifies Tempco products for precise heating and accurate temperature sensing in their application.